Stabilizing additive

GRANOCELL

developed for use in asphalt concrete mixtures with high bitumen content

Engineering background

One of the reliable solutions for increasing the durability of road surfaces is the use of SMA (stone mastic asphalt) and other types of asphalt concrete with a high binder content. Such compositions require the use of stabilizing additives that ensure structural stability and prevent segregation of the mixture during transportation and installation. The most widely used stabilizing additives are those based on cellulose fibers, due to their availability, high efficiency and ability to maintain the homogeneity of the mixture under difficult technological conditions.

60-95%

Finely dispersed cellulose fiber

5-40%

Finely dispersed structuring mineral materials

Scientific approach

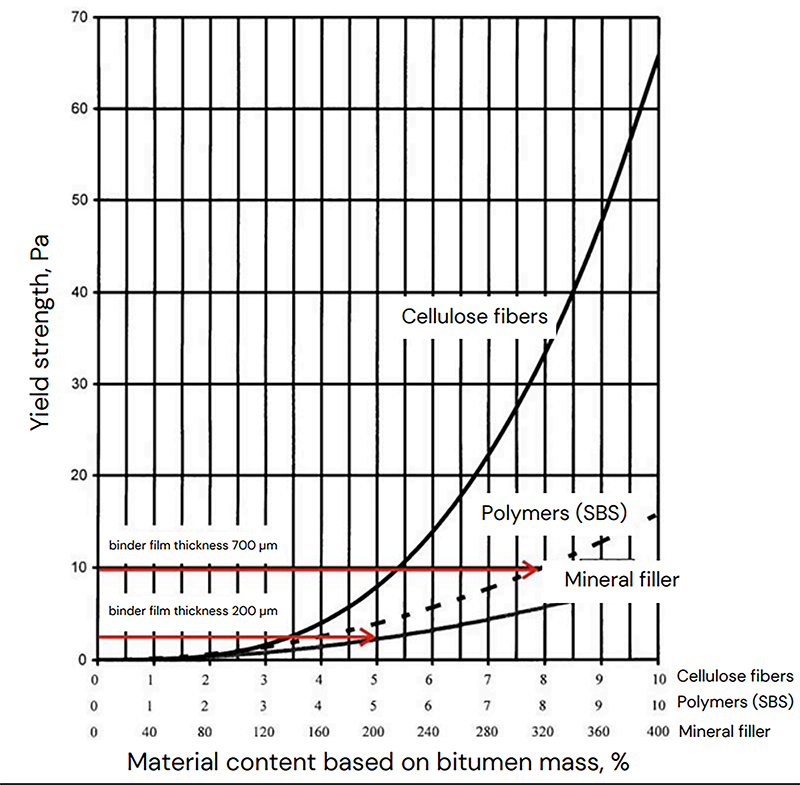

The stability of bitumen on the surface of mineral filler depends on a number of parameters:

- thickness of the bitumen film

- properties of organic binder

- asphalt concrete mixture temperatures

Scientific research shows that cellulose fibers are the most effective for ensuring the stability of the asphalt concrete mixture and preventing its stratification. Even when using polymer modifiers, in compositions with a high bitumen content, the introduction of stabilizing additives is required.

Our vision

We create a stabilizing additive that combines high quality, technological precision and scientific competence. Its key feature is the use of ultra-fine fibers that are aerodynamically mixed with finely dispersed mineral components. This configuration ensures uniform distribution of the additive throughout the entire volume of the asphalt concrete mixture, preventing agglomeration and entanglement of the fibers.

Technological features

Dosing

GRANOCELL has a high degree of convenience for automatic dosing due to its granular shape and density, which significantly simplifies the production process. This feature allows for precise and uniform addition of the stabilizing additive to the asphalt concrete mixture, minimizing the likelihood of errors in the composition of the asphalt concrete.

Mixing

The mixing time when using GRANOCELL is only 5-7 seconds, which has virtually no effect on the productivity of the technological process.

Heat resistance

GRANOCELL fully complies with the requirements of regulatory documentation concerning hot asphalt concrete mixtures. Granules do not burn under thermal influence, up to a temperature of 250°C. This guarantees the stability of the additive at all stages of the technological process: from the preparation of the mixture to its laying in the road structure.

Storage

The additive does not cake or clump during storage. The dried material does not absorb atmospheric moisture, which makes it resistant to external influences. However, the additive consists of natural organic fibers, so it is prohibited to store it in open areas, and it should also be protected from direct exposure to water to avoid organic decomposition. The material does not lose its performance properties during long-term storage.