Technical properties

GRANOCELL

Structural stability confirmed by laboratory data

- Granule diameter: 4-12 mm

- Granule length: 5-25 mm

- Humidity: no more than 10%

- Heat resistance: up to 250°C.

- Bulk density: up to 900 g/cm³.

- Cellulose fibers: 60-95%

- In asphalt concrete mixture: 0.20-0.45%

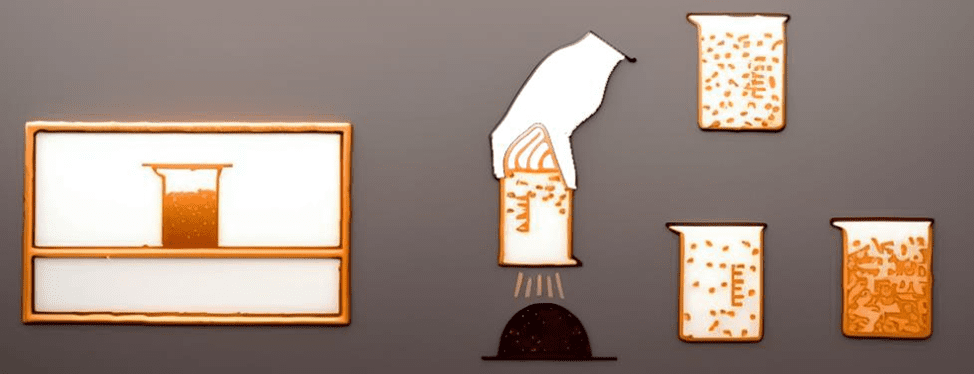

Tests

The binder flow method (the classic Schellenberg method) is used to determine the tendency of bitumen to separate from the mineral filler. This is important for assessing the risk of loss of structure and quality of asphalt concrete during laying. The test involves sample preparation, holding at mixing temperature and measuring the volume of binder flowing out. The results allow determining the required amount of stabilizing additives that improve the homogeneity of the asphalt concrete mixture.

GRANOCELL - technology with an economic advantage

The stabilizing additive GRANOCELL demonstrates high efficiency with minimal consumption, which reduces costs and increases the efficiency of asphalt concrete mixture production.

The optimal solution for high-quality and cost-effective production of road surfaces.

Conclusion

GRANOCELL is the stability of the asphalt concrete structure, confirmed by tests.

Our extensive scientific experience allows us to confidently solve problems of any complexity and scale. We strive for results that exceed expectations - and ensure sustainability that can be measured in time.

- Excellent quality

- High cellulose content

- Granular form

- Uniform distribution throughout the volume of the mixture

- Minimum consumption with stable effect

Ready to collaborate?

Contact us to schedule a consultation or learn more about our services.